David Prinselaar joined AkzoNobel in 2015 as the company was formulating a vision to transform the supply chain. While enthusiastic to make change, implementing a major transformation was, at that time, not straightforward. A thwarted hostile takeover and a new CE o revised the company strategy. In March 2019, Prinselaar was appointed by CE o Thierry v anlancker as Chief Supply Chain o fficer and member of the executive committee. It’s Prinselaar’s job to change the mindset and culture and encourage collaboration among colleagues as he drives the integrated supply chain transformation. “Supply chain is the backbone to the success of a company. It can add value to both the top line and the bottom line. Having successfully driven the functional agenda over the last years, the next step is to help the business become more strategic and competitive.”

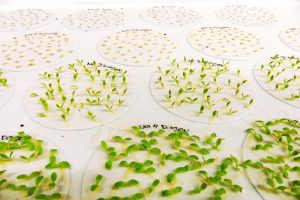

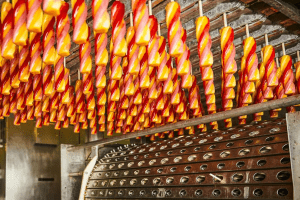

AzoNobel has a long history of mergers and divestments in paints, pharmaceuticals, plastics and chemicals. Headquartered in the Netherlands, it is active in over 150 countries and employs around 34,000 people. In 2017 it staved off a hostile takeover by US rival PPG. To help regain shareholder confidence it sold off its chemical division leaving two remaining divisions, decorative paints and performance coatings, and accelerated a rigorous transformation of its supply chains. Separate supply chains have been rolled into one to create manufacturing and regional synergies, that will improve service delivery and increase profitability. At the same time high performance paints and coatings that cool buildings, capture solar energy, improve aerodynamics and purify air, add value but call for greater agility in the supply chain. The transformation has resulted in significant job losses and changes in job responsibilities, especially in middle management. This disruption has not always been easy to swallow especially in a company whose history can be traced back more than 200 years.

How did you end up in your current role?

“Before we start, I would like to share my thoughts on the current biggest global challenge we all face as human-beings, the Corona virus. It is having an impact on our lives, our ways of working and on our perspective for the future, with many uncertainties and unknowns. It is obviously an amazing supply chain challenge, but ahead of this challenge, we need to keep our priorities clear – which starts by caring for the health of our families, employees and loved ones. Returning to your question, I moved around a lot as a youngster but ended up studying electro-mechanical engineering, specializing in mechatronics, in Louvain-La-Neuve, Belgium. After completing my five-year degree my aim was to travel abroad but, rather than back – packing, I wanted to live and work in a country. With my then future wife we decided to go to Malaysia. I was offered a job as project man – ager by a Belgian company that was installing pneumatic systems both in highway tool plazas and hospitals. It was a great two years’ experience but I then decided I should do something more traditional. I joined a large management consult – ing company in London knowing it would bring me in contact with many different companies. The company already had about 1000 consultants and was growing at a rate of 20% annually. Opportunities quickly came along and I moved up from junior consultant to senior consultant, project manager to senior analyst. It was a very valuable five years with much opportunity for strategic discussion typically with executive committee members who ask good questions about bottom line, speed of return etc. It was very fast and intensive, working 80 hours a week. I loved it, but then my first daughter was born and that way of working was not compatible with family life.

I resigned without another job to go to but within a month I had a position at a consumer goods company, Reckitt Benckiser. It was an agile, lean, focused company that gave me the possibility to grow quickly. I worked there for more than 10 years including periods in Spain, Germany, the USA, Brazil and finally in the Netherlands where I was responsible for the operational strategy for Europe and north America. It was an amazing learning experience with great assignments, but, after more than 10 years of continuous family moves across conti – nents, it was time for me to move on to a new challenge. I looked at different companies but in the end I was keen to join AkzoNobel because as well as having a supply chain function in the Netherlands it was also on the verge of a transformation. My new bosses Konrad Keizer and David Allen were both very motivated to transform the supply chain.”

Did the move to AkzoNobel turn out as you expected?

“At that time we had three business divisions: performance coating, where I was positioned; chemicals; and decorative paints (deco). We had 125 factories, 435 warehouses and 13 different supply chains, each with a different supply chain director so it was very complex. David Allen and I created a blueprint to integrate and create one supply chain for all the businesses; It took us nearly eight months and it would have meant enormous change. However, I quickly realized that it wasn’t going to be that easy to make changes in an established company with a long history. For example, one of my first trips was to Sao Paulo, Brazil, where we had four factories. Each business had its own warehouses and we had nine in total. I came back very enthusiastically because I saw huge opportunities to consolidate. However, even though my superiors were driven by a functional agenda and understood the benefits, any transformation of the business was still very much division driven so, for example, we had to keep deco and coatings sites separate. This philosophy changed, when suddenly in early 2017, PPG attempted to make a hostile takeover. Although it probably was a good proposal we believed we could do better. We decided to divest the chemicals division and create one focused paints and coatings company.

Was it a deliberate choice to merge the supply chains or was it a consequence of losing the chemical business?

“Carving out the chemical business and transforming the supply chain were two separate decisions. The supply chain transformation was also given more impetus following the appointment of our current CEO Thierry Vanlancker. The supply chain had been on the radar but Vanlancker has been much more receptive to a fully integrated supply chain. He sees it as a strategic advantage and ensured the Chief Supply Chain Officer is part of the Executive Committee. Previously we had 13 different integrated supply chains; now we have one to serve all the businesses. This has enabled us to create global roles, standards and initiatives. We have also been able to create synergies. Previously, of the 125 factories less than 5% was multi-business; each factory was dealing with its own local business. In the last three years we have moved a lot around to optimize our business and assets and now 40% is multi-business. We are much more global but at the same time we leverage the local and regional synergies.

What have been the biggest hurdles to the supply chain transformation?

“People and culture. Many people have had to give up some of their direct responsibility to the business and they are having to work with a new mindset. Probably the biggest change is the greater need to collaborate. To facilitate collaboration and avoid conflicts we have created formal programs as well as shared targets and incentives. Now we can also coordinate and synchronize the entire business through IntegratedBusiness Planning (IBP) which has helped us to collaborate in a structured way.”

What are the current challenges?

“Over the last four years the emphasis has been on driving a very strong functional agenda, building capabilities and establishing the AkzoNobel Leading Performance System, ALPS, a continuous improvement method that delivers on productivity. We have trained over 6,000 employees on foundational and primary processes to underpin this functional agenda. From 2020 our aim is to create a supply chain that helps grow the business. We can already demonstrate that profitability is at least at the same level as the competition and now we have to move for – ward to ensure that supply chain gives the business a competitive advantage. To achieve this our ISC strategy focuses on four building blocks; Firstly, end-to-end customer service. We want to start by fully under – standing customer requirements. This sounds logical but we often used to work on preconceived ideas; now we want to know exactly what customers want and where we can be more competitive. As the competition and environment evolve we have to understand how we can make the supply chain profitable for us and for our customers. As a result we have created different supply chain archetypes based on customer requirements. These differing archetypes allow us to manage complexity but within a certain framework and catalogue. Secondly; people, team and capabilities. Thirdly; operational excellence. Fourthly; optimisation of our asset network. We have 125 factories and 400 warehouses all over the world. The majority of ware – houses are outsourced. Our objective is to reduce the number of warehouses by 50 this year.”