“Supply chain is where the magic happens,” says Gustavo Burger, VP operations for Kraft Heinz, Europe, Middle East & Africa. His passion for serving and supporting the business is no illusion and he is a true believer in people first, followed by processes and then leveraging technology in the relentless pursuit of efficiency. “We can do anything in supply chain, from thousands of bottles to a very small batch, but everything has a price tag,” says Burger. The trick is to ensure that complexity does not strangle progress and to migrate the volumetric, middle mile business into a flexible last mile solution while sustaining the core business. His team is currently creating a touchless, self-learning organisation and it’s probably the first food company to have outsourced its planning activity.

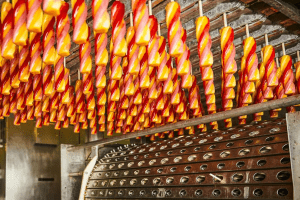

Kraft Heinz has a history going back more than 150 years. Heinz introduced its first tomato ketchup in the US in 1876 and the octagonal glass bottle was patented in 1890. By 1904 the iconic condiment was available around the globe. Kraft started as a cheese business in Chicago just a few years later. Over the decades both underwent many acquisitions and in 2013 Heinz was bought by 3G Capital. Two years later the investors bought Kraft and merged it with Heinz to create the fifth largest food and beverage company in the world with around 200 household brands. While many people would have been breathing through clenched teeth at the thought of an investment company taking over their iconic brands, Gustavo Burger says the investors simply take money from where it doesn’t work and invest it where it does work. This year it’s investing 100 million dollars in supply chain infrastructure in Europe.

The vice president operations EMEA describes the culture and daily challenges facing the supply chain as it undergoes continuing transition and the success of its Ed Sheeran ‘Edchup’ campaign.

You have a marketing background. How did you get into supply chain?

“I started at a very young age in my family’s sporting goods business in Brazil. My mother didn’t have any childcare during the holidays so she took me with her to the warehouse. As I got older I helped with deliveries, which I believe is where my passion for supply chain stems from. I had a 12-month internship with Adidas in marketing before returning to the family business. I worked in several roles including marketing and commercial before moving into supply chain where really I’ve been ever since. I’m passionate about supporting the business and having some control over efficiencies.”

What are the main challenges facing your supply chain?

“From a supply chain standpoint the FMCG industry is way behind other industries such as the motor industry. The biggest challenge is how we migrate this volumetric, middle mile business into a flexible last mile solution (direct to consumer). We are very good at fulfilling trucks but we need to develop more effective and efficient capabilities on delivering one case of product or one bottle of ketchup. We are asking ourselves, how should we make the transition and more importantly where do we want to be? We need to bring flexibility into our complex network to create solutions for the future. But, we need to sustain the core because that it what sustains this business we can’t lose our strength. It will be a staggered approach and it will never be a 100% transition to one single business model. The challenge is how to develop a platform for them to co-exist while being so different to each other.”

How are you approaching this challenge?

“We have already started on our planning area and the aim is to create a fully automated touchless organisation.

It has been a bold but simple approach. The strategy is built on three pillars: people, process and technology. We first made sure we had the right people in the right place with the right process for them to work: We knew it would be wrong to start with technology because our process was broken we had to fix that first before leveraging on artificial intelligence, machine learning, etc.. The result is that we believe we are the first food company that has outsourced its planning activity. This is the engine that connects the entire supply chain. It was a risk but it is running very well in Europe. All 13 factories including our Kitt Green factory in Wigan, UK, the largest food factory in Europe, are planned out of India. We are now implementing S&OP and network planning, and implementing scheduling all down line.

Now that we have the people and process in place we are starting to incorporate technology – robotics, artificial intelligence, machine learning – into the back of planning in a controlled way. Eventually, from the moment that we have an input, everything will flow automatically in a touchless organisation that is self-learning. Then we’ll move downstream onto automation and flexibility within manufacturing and coordinate this with planning.”

How do you achieve forecast accuracy, especially when planners are in India?

“In my experience the words forecast and accuracy are never compatible! If it’s a forecast it can’t be accurate. We believe in forecast collaboration using three streams – granularity, horizon and the ownership.

Regarding granularity: for some categories and products we don’t need a forecast at SKU level. We have 4000 SKUs but we don’t forecast them all the same way. We put effort where it matters and use statistics where it makes sense. With respect to horizon, sales own the short term forecast while marketing or trade own the long term forecast. And thirdly ownership: During S&OP feed back loops, collaboration cycles, etc, we work with just one number, one single source of truth so input is done by the person who has ownership of the figure at that point. We’ve defined these rules up front so there isn’t too much discussion. The machine runs the model and tells us the baseline . All the collaboration is to define uplifts and events that can impact the volume.”

What is your main concern in day-to-day operations?

“The relentless pursuit of efficiency – which is very different to cost cutting. We are an efficiency driven KPI organisation and we have to understand the real time operating efficiency: For example, in manufacturing we need to know what is happening now – not yesterday – so that the next shift can already make corrections. We are in the process of implementing technology to help raise our efficiency to a new level.

Even though we can create shorter lead times and faster change over times we are heavily dependent on food safety regulations. Sanitation is a big part of our business but here too we can use technology to clean and sanitise the lines in a faster way.”