Inspired-Search interview with Kees-Jan van Wees, Chief Supply Chain Officer, Zeelandia: “Better continuity thanks to focusing on least cost rather than lowest cost”

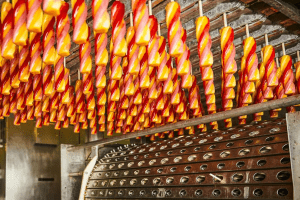

Zeelandia produces a broad assortment of bakery ingredients, ranging from bread improvers to cake and bread mixes and from release agents to edible decorations. Kees-Jan van Wees is the son of a cattle farmer: “As a young boy, my dream was to run a dairy.” After studying at Wageningen University & Research, he joined FrieslandCampina as a production manager in the Netherlands in 1989. He advanced through production and logistics roles at plants in the Netherlands, Germany, Belgium and subsequently Asia, gaining more and more responsibility, and eventually he had seen every aspect of the supply chain. “When I returned to the Netherlands in 2017 after almost six years in Asia, I got a call telling me that Zeelandia was looking for a Chief Supply Chain Officer who could get the supply chain ready for the coming decades.” Van Wees didn’t hesitate. After years of working for a multinational, he saw it as a great opportunity to have overall responsibility for the entire supply chain. “You carry the can when things go wrong, of course, but you also get the credit when things go right. Plus I like working for a visible shareholder – the farmers in the case of FrieslandCampina and the family members at Zeelandia. Another thing that makes it interesting to be a director of a family business is the contact with the Supervisory Board. The family has an interest in the company, but the formal contact goes through the Supervisory Board. So to get your plans accepted, you have to get all the parties on board, in addition to the company’s management team. I enjoy that challenge.”

Each family business has its own traditions that reflect the company culture. For example, Zeelandia gives its employees a gift to celebrate Saint Nicholas Day rather than Christmas. This tradition dates back to the ‘Hunger Winter’ of 1944, when the Ger- man occupying forces had flooded the Dutch village of Schouwen-Duiveland and almost all the employees had been dispersed throughout the Netherlands. The board of directors decided to send the employees regular food parcels to help them through that difficult time. Van Wees: “Fortunately there’s no hunger anymore, but the Saint Nicholas period remains important to us and we continue to uphold this tradition. A team of us spend an even- ing working on the assembly line to pack all the boxes ourselves. That’s illustrative of the solidarity within this company.”

How big is Zeelandia and what is your span of control?

“Our company has 3,500 employees across 30 operating companies (opcos), and around 2,000 of them work in the supply chain. I have ultimate responsibility for the whole chain: plan, source, make, deliver plus everything we need for our license to operate, such as employee safety, the environment and sustainability. Zeelandia has 25 factories around the world, most of which are in Europe. At group level, 20 people are employed in supply chain at our headquarters in Zierikzee, each with their own specialism – such as sourcing, contract management, logistics, S&OP or engineering – as well as lots of people with the necessary technological knowledge for our factories. That’s important because we need to continuously update our factories in order to stay at the forefront of the market. In addition, we’re currently building four brand-new production sites: in China, Russia, Belgium and Brazil.”

How does your supply chain look?

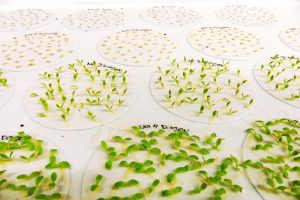

“Our 25 factories produce for the domestic markets, for inter- company orders and for export to about a hundred countries. We source our raw materials from all over the world. We purchase the bulk raw materials – accounting for approximately 65% of what we buy in – centrally.

The rest of the purchasing – mainly specialties and products to suit local tastes or cultural preferences – is decentralized at the opcos. All our opcos purchased locally in the past, but we’re now trying to increase our centralized purchasing by looking closely at where it can be beneficial. However, central buying is not an end in itself, but rather a way of increasing the availability of raw materials and, where possible, driving down the price. We’re in the midst of a transition to this new model.”

“The majority of our customers are local bakeries – small and medium-sized businesses (SMEs) with a handful of stores – but we also supply to big industrial bakery companies. Our strategy is focused on being able to meet our customers’ needs for single sourcing, which is why we offer such a broad product range. We supply every ingredient that a baker or pastry chef could need. The baker’s success is our success.”

What are the key supply chain challenges for your organization?

“There are two short-term challenges. The first is the global shortage of raw materials, which is partly caused by the pan- demic. Supply and demand have been out of balance since the coronavirus outbreak. Some factories had to shut temporarily. There is a shortage of labour for harvesting activities due to travel restrictions. Then once the crop has been harvested, it’s difficult to find transport capacity, because shipping containers are in the wrong place and there’s a shortage of truck drivers. As to make matters worse, harvests around the world are suffering due to cli- mate change, which will continue to contribute to harvest unpre- dictability in the years ahead.”

“Secondly, the market is becoming increasingly volatile, and this is once again linked to the pandemic. Most bakeries were allowed to stay open during the global lockdowns, but many consum- ers preferred to buy their bread at the supermarket during their weekly grocery shop. Cake sales were hit even harder, sometimes falling to just 20% of the usual volumes. After all, there were no birthday parties or other celebrations. Consumers eventually started coming back because they missed the delicious bread and pastries from real bakeries, but due to the uncertainty, bakeries switched to placing smaller orders more frequently. In addition, consumers are becoming more demanding. People are taking a more conscious approach to what they eat – not only in terms of nutritional value, but also product origins and sustainability.

All in all, these developments are significantly increasing the demand volatility.”

Which long-term challenges do you foresee and how are you preparing for them?

“In the coming years, one key question will be how can we differentiate our supply chain, and to what extent? Our customer base is not uniform; all our customer groups have different wants and needs. Up until recently, we delivered to all our Dutch custom- ers once a week. Now, we deliver more frequently if customers request it. But we also have to consider the costs – especially because here in the Netherlands we handle the distribution our- selves; our drivers deliver to customers’ doors and also provide advice as part of the service. That’s a wonderful model, fully focused on customer intimacy. But bakeries don’t always need advice, and it’s necessary to have more flexibility in the delivery times to optimize the load factor. So we need to increase our differentiation in that area and find the happy medium between added value and cost. We need to find a model in which the costs and revenues are balanced: least cost rather than lowest cost. The same holds true for our factories, where we also need to differentiate more. In the past, all the factories made roughly the same products, but we’re going to change this too. We will be focusing on allocation in the years ahead. This was completely unexplored territory before I arrived, but we’re now taking cautious steps. We have 65 product groups, but we don’t have an infinite amount of capex to invest in production lines. So we’re now making considered choices to invest in a particular technology at a particular factory and then to make that the European production centre for a particular product.”

How do you decide how your footprint should look for the coming years?

“There are lots of things going on. There’s an increasing drive for innovation and a need for more efficiency, but the supply of capex is limited and the European labour market is tight. We can monitor some developments perfectly well from our headquar- ters, such as the labour shortage. We know which countries are still problematic and where it’s less of an issue, and we can tai- lor our investments in further mechanization and automation accordingly. On the other hand, we can’t think of everything for all our factories from our headquarters; some things call for a local approach. In Spain, for example, we have a factory that spe- cializes in water-based bakery fillings. They’re involved in open innovation and they’re now being approached with interesting ideas by some of our other opcos and also by suppliers from Tur- key and India. We want to continue to stimulate local initiatives of this kind. At the same time, we have shown – especially during the pandemic – that it’s nice when the headquarters can relieve you of some concerns. Take the sourcing of the basic raw mate- rials. If the local factories had still been responsible for that, we would have had severe production issues. But thanks to sourcing 65% of our raw materials centrally, we could continue to guaran- tee high product availability. That came in useful when the mar- kets recovered because Zeelandia was able to set itself apart from competitors who weren’t able to deliver.”

What does this mean for your sourcing strategy?

“Sound contracts with our suppliers are a key factor in our deliv- ery reliability to the market. We don’t just go looking for the low- est price; we want to build long-term, win-win relationships, so we’re focusing on a handful of core suppliers for each raw mate- rial. Sometimes that means scaling up and sometimes scaling down. Close supplier relationships are not only important with a view to supply reliability, but also in relation to innovation. We’re in the process of setting up an S&OP process with our suppliers. You don’t do that with just anyone; there has to be sufficient trust, and that’s also a reason why we’re focusing on a few core suppli- ers per raw material. Needless to say, you don’t build a relation- ship by going for the lowest price and then merely placing your orders. That’s why we always talk about the ‘least cost’ rather than the ‘lowest cost’. This strategy has benefited us greatly, especially in view of all the coronavirus-related challenges over the last two years, and we’ve learned a lot of valuable lessons for the future. Incidentally, a good supplier relationship doesn’t always mean that we can obtain all the raw materials we need on time; our suppliers face challenges too. That’s why we’re taking a close look at our recipes to see whether we can offer the same end-product functionality using a different blend of raw materials. So we’re investing heavily in recipe management and optimization, and we’re good at that – our company has 122 years of experience, after all. As a family company, business continuity has always been of paramount importance to us and in this ‘new normal’ we’re now reaping the benefits of that mindset more than ever before.”

How has your company coped with the coronavirus crisis?

“At the first signs of impending lockdowns we immediately set up a crisis team, which is headed up by me and meets every Thursday. Clear instructions are needed to protect the health of our employees. In addition, we immediately started to build stock and we focused on two KPIs: continuity and safety. Things like optimizing profit and working capital took a backseat for a while. Thankfully, we are financially healthy enough to be able to prioritize keeping our people safe and ensuring delivery reliability for our customers. Always being able to supply to our custom- ers, no matter what it takes, forms the foundation of our success. Incidentally, we had started phasing out our crisis team meetings last summer; we were meeting only once every two weeks and looking at how we could transform COVID-19 into a governance issue, when the fourth wave flooded Europe. We’re now back to weekly meetings.”