Bleeker started his career as a consultant at what was then still known as Andersen Consulting. Just when he had decided that he wanted “a more hands-on role rather than just giving advice from the sidelines”, he became involved in the merger between De Boer and Unigro. It was the perfect moment for him to make the switch from the consultancy side to the client side. After first integrating the front end of the two grocery businesses, he then integrated the back end: the distribution centres, logistics networks and the supply chain management software.

After completing that integration, he did a similar thing at Van Uden, a logistics service provider that had grown rapidly by making several acquisitions but was struggling to leverage sufficient efficiency gains from its larger size. He ended up being managing director of Van Uden for nine years, until he reached a point when he was hungry for a new challenge. “I took a sabbatical to think about my options and that’s when I became involved with Picnic.”

What attracted you to the start-up?

“The great thing about launching a new company is that you can start from scratch. We had a shared dream: providing free home deliveries of groceries every day within a 20-minute time slot. That’s unbelievably difficult, because supermarkets work with three different temperature categories: frozen, chilled and ambient. Getting deliveries of products from all three categories to people’s homes successfully is complex, especially when very short lead times are involved. Customer satisfaction is largely dictated by whether the delivery is complete and on time. It doesn’t matter how great your web shop is or how cheap you are, if customers can’t trust your indicated delivery times or are repeatedly confronted with missing items, they won’t come back. The founders of Picnic have lots of e-commerce experience but they were less familiar with food retail logistics, so the fulfilment team were given a lot of freedom to design the set-up themselves from the start.”

What’s the key supply chain benefit of smart data management?

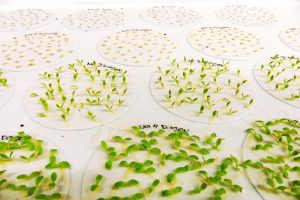

“Without a doubt, the biggest advantage is that we avoid perished products and out-of-stocks by making very good forecasts – and we’re getting even better all the time. Our forecasts are at product level and fulfilment centre (FC) level rather than at customer level. Take bread, for example. It has a short shelf life and comes in many different shapes and sizes. As a result, this product group is the source of quite a lot of waste and out-of-stocks in most supermarkets. We tackle that by staying as agile as possible. At the end of every workday, we share our forecast for the next day with our bakery suppliers. We accept customer orders for the next day up until 10 p.m. We’ve agreed with the bakeries that we can adjust our definitive orders with them up until that time. As a result, the next day we receive precisely what our customers have ordered. In fact, we’re now even moving towards ultra-fresh bread which is supplied to us three times a day. We do exactly the same thing with fresh produce, and in particular fresh-cut vegetables. At the end of each workday we make a forecast based on the orders that we’ve received up until then. We then fine-tune that just after 10 p.m. when all the orders for next-day delivery are in. This approach means that our customers receive a much fresher product than they would when going to the greengrocer’s or a different supermarket. And, as I said, we don’t have any waste.”

How does your supply chain look?

“In mid-March we will be opening our sixth FC in the Netherlands and our third in Germany. Besides the FCs, we have 50 hubs in the Netherlands and 20 in Germany. Today, five years on, our FCs are running well. We know how we need to design the processes, we know which KPIs we need to use to measure whether processes are running effectively, we have a clear understanding of how the FCs and the hubs need to be aligned, and we’ve continuously developed the software to the extent that it’s now more or less mature. My colleague Peter Renting joined us from Unilever and is responsible for all fulfilment operations within Picnic, while I’m now focusing on our DC operations. We found it necessary to open our first distribution centre (DC) last year and our second this year because our sales growth meant that we’d outgrown the Boni grocery chain, which initially supplied all our FCs. So we now have one DC of our own for chilled and ambient, plus a second DC for the longtail ambient. The leading suppliers of fresh items deliver directly to our FCs. To be honest, I see the DCs as a necessary evil – they are an extra step that I’d rather not have because they add extra costs that I’d prefer to avoid. We’re stuck with them for now, however, because our suppliers aren’t as agile as we’d like. So we need a DC to absorb fluctuations in demand. When our business was still small it was relatively easy for our suppliers to adapt if we increased an order at the last minute, but that’s no longer possible now we operate on a much larger scale.”

How are the FC processes set up?

“On average, a total of around 400 people work in each FC. The orders are largely picked manually; we still have a relatively low level of automation. So far we’ve preferred to work with manual processes because that enables us to open a new FC within 10 to 12 weeks. Having said that, we’re working on designing our first fully mechanized FC which we expect to be able to handle five times as much volume as a manual FC. However, this takes time because although we intend to use existing mechanization systems, we want to control them using the software that we developed ourselves – and that software aspect is time-consuming. By the way, there wasn’t an existing solution that met our specific needs for loading the bags into the crates, so last year we worked together with a Dutch company to develop our own bagging machines.

We hold very little stock in the FCs. We have maximum one day’s worth of stock of fresh products, and two to three days’ worth of ambient products. Whenever we open a new FC, we limit the number of new customers we accept in the initial period and scale up gradually to give our employees time to settle in and get to grips with the processes. Our concept is easy to replicate in other countries; our FCs in Germany are pretty much a copy of the ones in the Netherlands. Thankfully, we don’t need our own DC in Germany yet because there we work together with the country’s biggest retailer: Edeka.”

How does Picnic’s culture differ from that of other companies?

One thing that’s special about us is that we’re never afraid to admit that we’re on the wrong track and need to do things completely differently. We have the guts to throw existing structures overboard if we realize in hindsight that a different approach is more effective. We don’t just soldier on out of a fear of change. We also take care to recruit people who are a good fit with our culture. The two most important criteria for us are entrepreneurship and not being afraid to take responsibility. For example, during job interviews it’s not unusual for us to present candidates with a current challenge or even to ask them to participate in group discussions, because we don’t believe that anyone should be allowed to hide behind the excuse of ‘I don’t work for you yet so therefore I don’t know’. Once you’ve got a basic understanding of the situation, you should be able to form an opinion – and you shouldn’t be afraid to express it.”