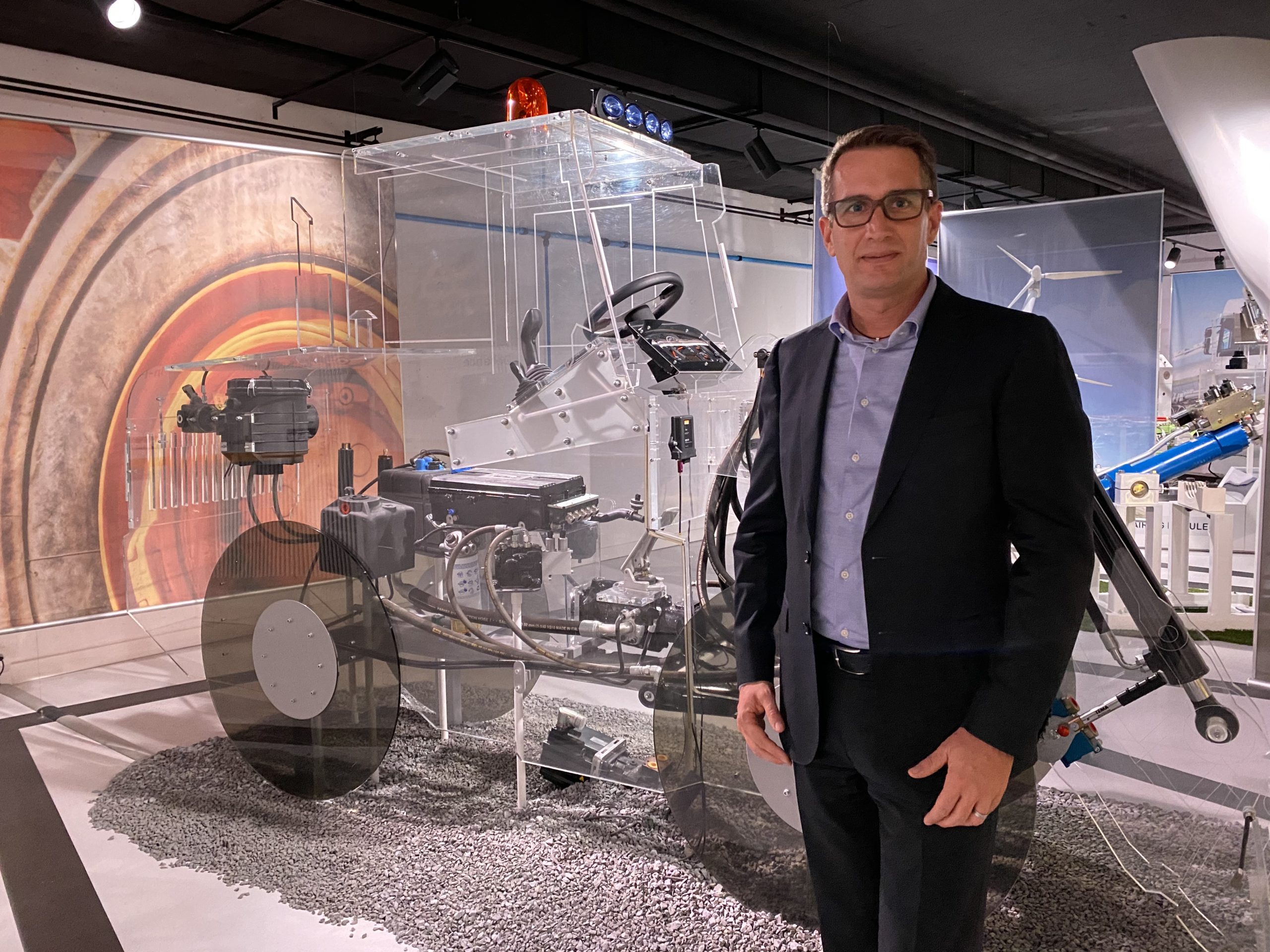

Inspired-Search interview with Frank Baur. Frank Baur joined Parker Hannifin two years ago to lead its EMEA supply chain from its regional headquarters in Étoy, Switzerland. The company manufactures a wide range of products that facilitate motion within an industrial application, which, put simply, ‘enable engineering breakthroughs that lead to a better tomorrow’. “I was attracted to its winning culture, passionate people, engaged leadership, and true focus on valuing customers,” says Frank. Running a decentralized, end-to-end supply chain with responsibility across six groups, 19 divisions and 27 countries, he seeks competitive advantage through the core lean management principles of continuous improvement and creating value for customers. Eight months after the start of the Covid-19 pandemic, the company remains strong. This, as Frank explains, is due to its customer centricity and engaged people, which comes from its philosophy of ownership, entrepreneurship and decision-making at the lowest possible level.

Parker Hannifin is a leader in motion and control technologies and has a long history of powering machines that changed the world. From brakes and fueling systems for aerospace to valves and sensors for climate control, power generation and healthcare, it touches all parts of our daily lives. Founded in 1917 in Cleveland, USA, by entrepreneur Arthur Parker, it has a deeply engrained culture of innovation and commitment. At the turn of the Millennium the global company introduced its successful Win Strategy, which was revised in 2015 and 2019 to focus on the customer experience, in order to improve productivity and profitability.

With sales of 13.7 billion dollars in fiscal year 2020, Parker has come through the Covid pandemic in good health and, with Frank at the helm of the EMEA supply chain, improvements are set to continue. “Supply chain is driving the competitive advantage that enables Parker to be a top-performing company,” he says.

How did you get to where you are today?

“I studied economics in Germany and, after graduating, went directly into supply chain management. I started in fast moving consumer goods and then joined a consultancy, Ingenics, before moving into industry to work for Robert Bosch. While there, I had the opportunity to move to Brazil to lead its Latin American supply chain and then to Chicago, where I had responsibility for its NAFTA supply chain.

Working for Ingenics was also an important step because I learnt to work with standard methods and had my first exposure to industry. The firm is strong in operations and process management, so it gave me a solid foundation for manufacturing. It also exposed me to the importance of talent management and this remains key in my current role. My time as a consultant also boosted my cultural awareness and inter-cultural competencies. It was the first time I worked on projects outside of Germany.

I joined Parker Hannifin two years ago. We are organized in six groups and I am responsible for the supply chains of 19 divisions, which are differentiated by product or customer. Each one of those 19 divisions has a supply chain organization with decentralized operations that puts them close to our customers and to our supplier base. This gives us a competitive advantage over larger-scale, centrally-led organizations. It is a truly holistic end-to-end set-up across all functions and, for me, the leadership challenge is to lead remotely.”

Do those individual divisions report directly to you and how do you leverage the benefits from one division to another?

“Each of the 19 divisions has a general manager who is responsible for targets and makes first-level decisions. The divisional supply chain leaders report back to me, which ensures functional guidance and the transfer of knowledge and technology between divisions.

In addition, the functional owners of transportation, sourcing, procurement (direct and indirect), material management (S&OP, inventory, service), logistics, warehousing, foreign trade management and compliance also report to me.

We have 13,000 associates in EMEA but only about 110 at our regional headquarters. Each year, we transport around 1 million shipments from 100 warehouses and 100 manufacturing locations in Europe. We do have facilities in other parts of the world for risk mitigation, but our aim is to produce in Europe, for Europe.”

What are your current supply chain challenges?

“Covid-19 has been unprecedented. During the pandemic the supply chain has been at the sharp end of the company because we have had early engagement with customers and suppliers alike.

We run our business with a globally-aligned strategy and safety has always been our top priority. Within EMEA we were on track regarding safety and, when the crisis started, we expanded the principle of keeping people safe, not just at work, but also at home. The advantage of being global was that we could take our Covid experience from Asia and apply it across Europe too.

For me the main challenge in this crisis has been sourcing. However, we have been able to leverage our strong local-for-local footprint. More than 85% of our sourcing volume comes from long-term agreements with suppliers and a significant amount is dual sourcing. This significantly mitigates any risks, and we have been able to maintain our manufacturing capacity, a huge accomplishment of which I’m very proud.

Secondly, we invested early in transportation visibility. Whether picking up goods from suppliers or delivering to our customers, some 99% of our freight is transparent. We have 12 preferred carriers who do 86% of our transportation. This has led to very honest partnerships, which gave us early awareness of where the outbreak was impacting us.

Thirdly, our focus on talent and people engagement has helped a lot. As the impact of the crisis increased, having smart people who were able to analyze big data cubes and combine this with material management and planning, made the difference. By empowering them and adjusting our reporting, it gave us the necessary transparency to manage the crisis and we didn’t let manufacturing down at all.”

These are challenging times and you have 19 divisions with decentralized responsibilities. How do you gather information to get a complete overview of what is happening in each market and how does this differ from previously?

“In operations, for example, the entire leadership team met daily during the first stage of the pandemic, but the execution was not much different to usual. It was a question of leveraging data. Over 90% of our transactions are in one system, which gives us transparency and allows us to find a top solution. We had already mapped supplier resilience for financial reasons and within one week we had added their operational capability: Are they operating? Do they have enough workers? Are they delivering the projected output?

Because we had already invested in the availability of data, we were able to combine it with information from our transportation partners. It was extremely helpful at the beginning of the pandemic to have engaged, capable people available to do this. In June we reviewed our supply chain strategy and saw that we did not need any major changes. Covid-19 has not impacted our strategy, even if it did accelerate certain issues.”

How do you assess the supply chain strategy?

“Parker’s great advantage is that we have guidance from our Win Strategy, which is based on four essential pillars. The first pillar is engaged people, which boils down to functional expertise, pipeline strengths, diversity, inclusion and continuous learning. Before the crisis we had conducted our annual empowerment and engagement survey, which showed that the company performs very well against its peers and that the EMEA supply chain is best in the region.

During the supply chain review we quickly concluded that talent management remains key. We need to continue with our pipeline fill across all levels in the supply chain organization and further accelerate our graduate trainee program. On October 1 we launched an internal supply chain academy to further strengthen functions and experience.

We aim to have engaged people in cross-functional teams who are empowered to make decisions at the lowest possible level. At Parker we call these High-Performance teams (HPTs). Before the crisis, 78% of associates were in a high-performance team. This meant they were working together with a defined purpose and clear target, often remotely, to solve a problem. The crisis truly changed the way we interact, because we used more video-conferencing platforms, but it also accelerated the use of HTPs.”

In this era of remote working how do you manage to keep employees engaged?

“Two ideas that reflect my own management philosophy, and that of the organization, are ownership and an entrepreneurial mindset. If I own a topic and can drive it, then I will still do that even during difficult times and in a remote environment.

Secondly and maybe more importantly is continuous improvement, the foundation of lean management. Continuous improvement, together with ownership and entrepreneurial mindset, is the way to engage people. And when we allow decision-making at the lowest level, we are empowering people to deliver fantastic results, as we can testify. Remember that we already had a decentralized business set-up. Our safety-first mentality and culture meant that we could adapt relatively quickly to the crisis and establish a hybrid work model. We continue to see the benefits.”

Supply chain is often internally focused so how do you ensure that your associates engage with customers in order to improve supply chain?

“The second pillar in Parker’s Win Strategy is customer centricity. Our customer service and the supply chain organization are inter-linked. We get involved with customers at an early stage in the process, from product development to day-to-day execution. Engineered products are a constant challenge in terms of managing complexity, so this early engagement is essential in order to manage this complexity. A supply chain associate will often join discussions with a key customer. We need to know the expectations in order to deliver quality products, on time and in-line with the agreed lead times. Our end-to-end setup makes that possible.”

How do you achieve end-to-end visibility and how far does it extend up-stream and down-stream?

“A source-make-deliver supply chain is about having transparency, being able to influence each step, and, more importantly, being able to identify any risks or outliers in functional areas of the supply chain. This is one of our key strengths: Plan for Every Part. Product delivery does not end at the point where the product is delivered. We know the markets for our applications and we use this information at an early stage to plan capacity. We also have early engagement with the turn-part supplier, discussing raw materials (such as steel) and where they are sourced.

Technology does play a growing role. Like many of our customers, we use “should cost tools” in procurement, for example. And as mentioned earlier, we have end-to-end visibility for transportation. We are currently working on the deployment of a global transport management system.

We have also undertaken a big initiative to boost the transparency of the indirect spend of our sourcing. Indirect spend should not be underestimated. It is large, but visibility is often limited. By the end of June 2021, 70% of locations and 50% of indirect spend will be managed through a new cost management tool to give us 100% transparency.”

How has the Parker Win Strategy further strengthened your ability to come through the pandemic?

“Our third strategic pillar in supply chain is risk management, including maximizing supplier resilience. We had already proactively identified the risks and assessed supplier agility, their ability to provide short lead-time products within a framework of long-term agreements.

The fourth pillar in the Win Strategy is cash generation, which has been very important to us during this crisis. I am particularly proud that the supply chain organization has performed so strongly in both areas that we are able to impact inventory and sourcing. We were a reliable partner for the market and our internal organization worked very well, enabling us to strengthen our cash position during the pandemic.”

How do you achieve a fast return on inventory to enhance cash generation?

“As a strong believer in lean, and with our customer-centric philosophy, I believe that the closer we are to the customer and the earlier we are engaged in the engineer-to-order cycle, the better we can manage demand. When we use this information in a structured way we can quickly adapt our manufacturing lines.”

With your aim for continuous improvement, what role does technology and digitalization play in each functional area?

“My aim is to drive a competitive advantage by using state-of-the-art technology to ensure seamless service in an end-to-end environment. The first step is to understand the problem, then do a solid route-cause analysis and solve it. If software or technology can help, that is perfect, but in my 25 years of experience, a new tool has never solved the problem if I didn’t understand that problem first.

My move from fast moving consumer goods to the automotive sector was motivated by my desire to learn the Toyota Way and thus eliminate waste through continuous improvement. Once we have eliminated waste, then we can automate.

For example, at our biggest warehouse in Bielefeld, Germany, a site of true excellence, we have already invested in new logistics technology. We used to move materials with forklift and a driver, but these have been replaced by automated guided vehicles (AGVs). This has been in response to Covid, because we don’t want people moving from one functional area to another. This is fully in-line with our culture of safety-first. Further robotic solutions will come, mainly for ergonomic reasons, and we will invest capital accordingly.

Sales and operations planning has already been further automated to recognize patterns and outliers during big data analysis, which we basically use for demand sensing.

In general, we have not purchased new tools to forecast demand, although we are currently working on a pilot. We want to use data to further improve customer experience and our cash position.

Currently more than 90 per cent of our customer and supplier interactions are on one ERP platform and that data base makes it possible to access and analyze lots of information.

We had gained a lot of volume and complexity from acquisition, so the planning process inevitably contained some waste. We needed to eliminate waste, and we have since been able to automate the planning process within our ERP environment.”

Do you carry out collaborative innovation with suppliers and what is the role of digitilisation?

“We engage very intensively with suppliers and that is very important. Technology per se is not changing our approach. But technology and IOT do change our product offering, both the production process and the individual parts.

Likewise, I want to bring digitalization into our ‘buy, make, deliver’ supply chain. For example, procurement used to be done mainly by negotiating prices. Now we can apply some of the tools already used in the industry to produce 2D and 3D drawings that we can upload and use as the basis for negotiation. Also, robots are automating repetitive work, allowing our people to spend more time in dialogue with our suppliers.”

Supply chain is often seen as a cost generator. How did you turn the organization from being cost focused to profit focused?

“Fortunately, the supply chain at Parker is seen as more than just a cost contributor. Strengthening our cash position by adapting our inventory levels is essential. But we have to do it in a clever way and keep inventory low without impacting the customer experience. If it only improves the financial cash position, then we will be unable to provide the goods-to-order. And this will impact the customer experience.

Product portfolio management is key because it is the starting point for the entire inventory management process. Customer engagement remains highly important throughout when managing the complexity of product life-cycles. You need a plan for every part, based on where the part fits in the individual product life cycle. This ensures the highest levels of service and the lowest possible inventories.

We learned a lot during 2008/9. We brought in tools, knowledge and training so that our people are more capable now to execute accordingly. This pays back in the end.”